Automated movement for enhanced manufacturing

Promation Robotics

Promation’s three decades of robotics experience truly delivers. With global experience in numerous industries including automotive, nuclear and aerospace, we offer robotics expertise in a wide variety of applications and environments—all while maintaining a stringent focus on quality tooling equipment and cost.

Robotics systems

Promation has a very broad robotic expertise, ranging from off-the-shelf industrial robots to custom Cartesian systems. Promation has the capacity to develop custom robotic solutions to meet customer requirements for cost, productivity and on-time delivery. The solution may consist of a single robot cell or multiple cells with multiple robots for more complex manufacturing systems. Promation can integrate robotic systems with AGVs, including Automated Material Handling systems. We have large and small robotic solutions for all types of customers, including large OEMs and smaller companies. We support all of our systems with superb after-market service and support.

Pushing the limits

More than just another robotic integrator, Promation pushes the limits of robotic technology to help our customers achieve the real ROI. While standard out-of-the box industrial robots may satisfactorily do the job they were intended for, our decades of experience and commitment to R&D means we can custom-tailor a robotic solution that does more than you might expect.

Flexible manufacturing cells

From stand-alone manufacturing cells that steam fabric for car seats, or robots that install car seats themselves, the Promation team are experts at designing, testing and installing scalable manufacturing systems to speed up the manufacturing process. Ask us how customized manufacturing cells can reduce your reliance on manual labour, increase the accuracy of your lines, free up staff for more involved tasks and increase efficiency.

Partnerships with top global robotic manufacturers

To ensure our customers get the best, most durable and cost-effective solutions possible, Promation partners with the world’s top industrial robot manufacturers. When you choose Promation to develop a robotic solution for your plant, rest assured we only use the best robotic equipment available on the market.

Our robotic capabilities

Our Application Engineers have an extensive library from our past robotic implementations to choose from. Using tried and tested designs, they can quickly reconfigure and add new design to complement the entire solution. The engineers can simulate the application with use of specialized simulation software including:

● PowerMill Robot

● Fanuc Roboguide

● Moduleworks Robotics package

● MotoSim

● KukaSim

For larger and more complex manufacturing systems we use advanced simulations such as FlexSim and others.

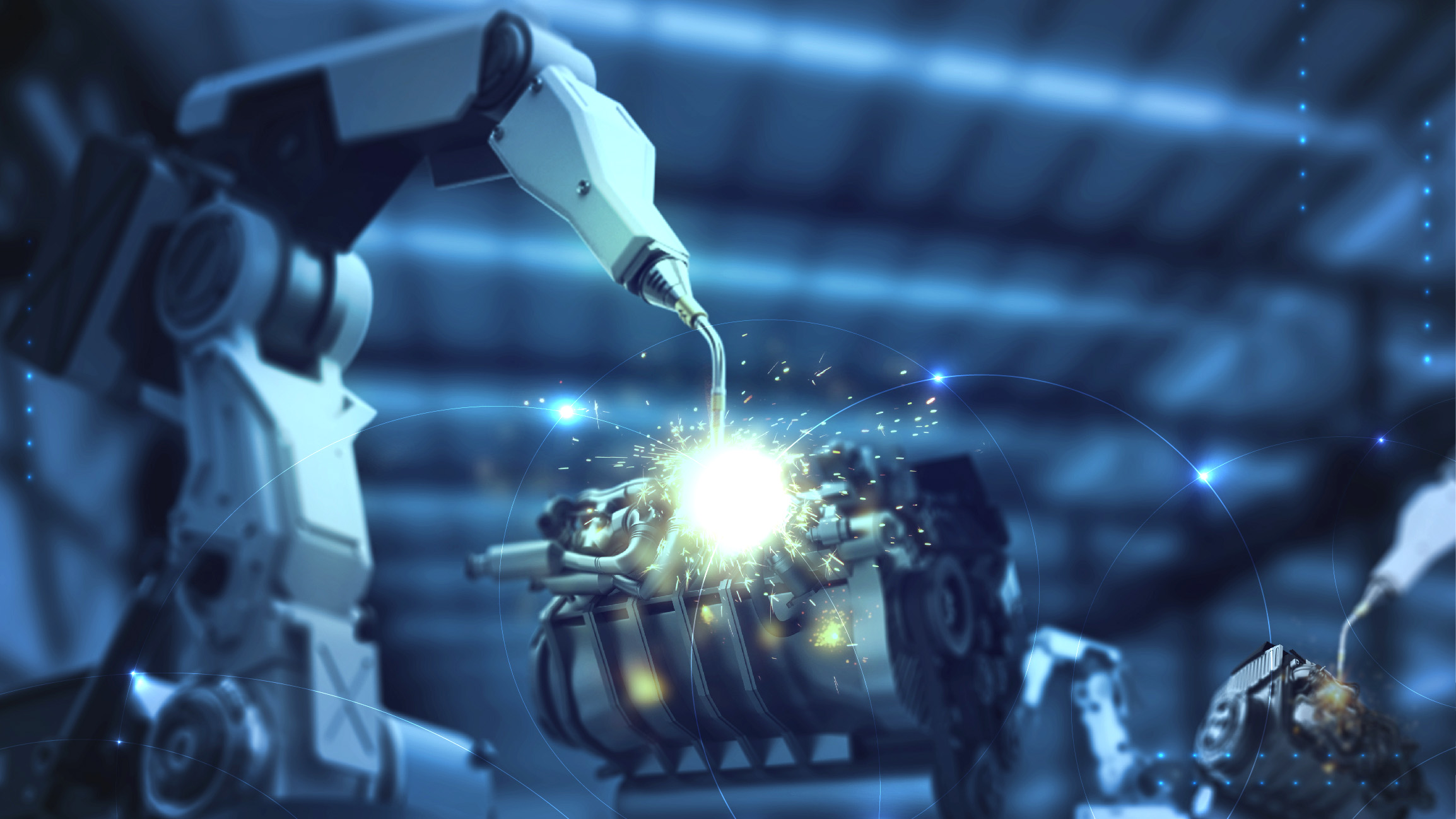

We support advanced simulation for additive manufacturing, Waterjet, welding and subtractive operation. This includes developing the CAD-based toolpath for the robot, including collision checking and singularity avoidance.

Promation has expertise in a multitude of applications for manufacturing. This expertise allows us to quickly select the best robotic solution, which may consist of single or multiple applications tailored to the Customer needs:

● Assembly: pick-and-place, insert, torque, bin picking

● Joining: welding, gluing, riveting

● Cutting: Waterjet cutting, spray applications

● Subtractive Manufacturing: milling, grinding, polishing

● Additive Manufacturing: 3D Printing of metals, plastics and other materials

● Material Handling: packaging, palletizing

● CNC Machine Tool Tending: multi parts, automated chucking, inspection

● Inspection and Test: vision, laser scanning, touch probe

● High-Speed Conveyor Pick and Place, Labeling, Tracking

● Cartesian XYZ large-area handling and storage

Promation has vast expertise in robotic types and configurations. Promation’s application engineers can select the best robotic configuration to fit customer requirements closely and cost-effectively. Our engineers are very fast and effective in preparing the best solution for the application. They can choose from our library of solutions including:

● XYZ Cartesian robots for speed and precision at low cost

● 6 axis industrial robots for flexibility and reach

● Additional auxiliary axis can be added for extended reach (5m, 10m, 15m and more) for specialized processes such as welding or additive manufacturing

● 7th and 8th axis for welding and additive manufacturing

● Hexapod and delta robots for high speed and precision pick-and-place

● Cobot for collaborating with humans in a safe and accessible environment

Front Seat Install

A large automotive EV OEM needed a better method of installing car seats.

Featured Work:

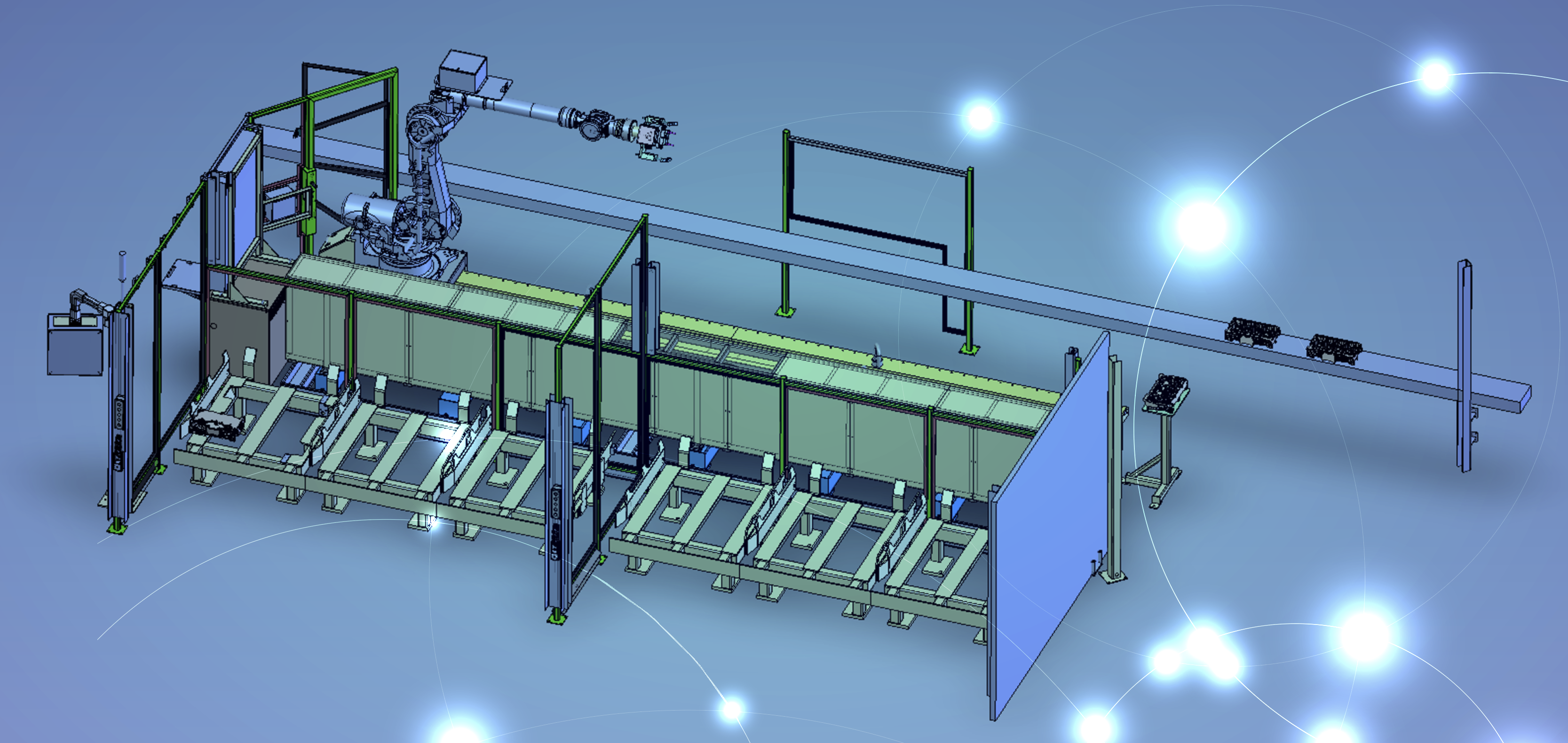

Robotic Palletizer Expansion System

The robot would be an addition to an existing 4-Cyl. Engine Head line creating a required buffer to even-out throughput. The robot would pick parts either from the conveyor line directly into available positions in the buffer or be flexible to also handle pallets. Either way, the robot with vision should accommodate each position to pick up and do the same on drop off. The elevation matters, so the robot program had to be very precise. The system consisted of a 6-axis robot mounted on a linear axis for additional reach, with a custom-designed pick-and-place gripper and guiding the robot position with a vision system, while also having access to direct pallet infeed or by picking directly from the line.