Assembly Build Line Conveyor Systems

Proven Conveyance Solutions

Promation Engineering is a leader in pallet-based assembly lines. From seats to instrument panels, bumpers, center consoles, mobile trailers, washer and dryers and electronics: we have you covered.

We are a single-source, full-service automation company that delivers value and consideration first. We provide full electrical and mechanical engineering for our customers, including turn-key, end-to-end project management and system integration combined with after-install support throughout North America.

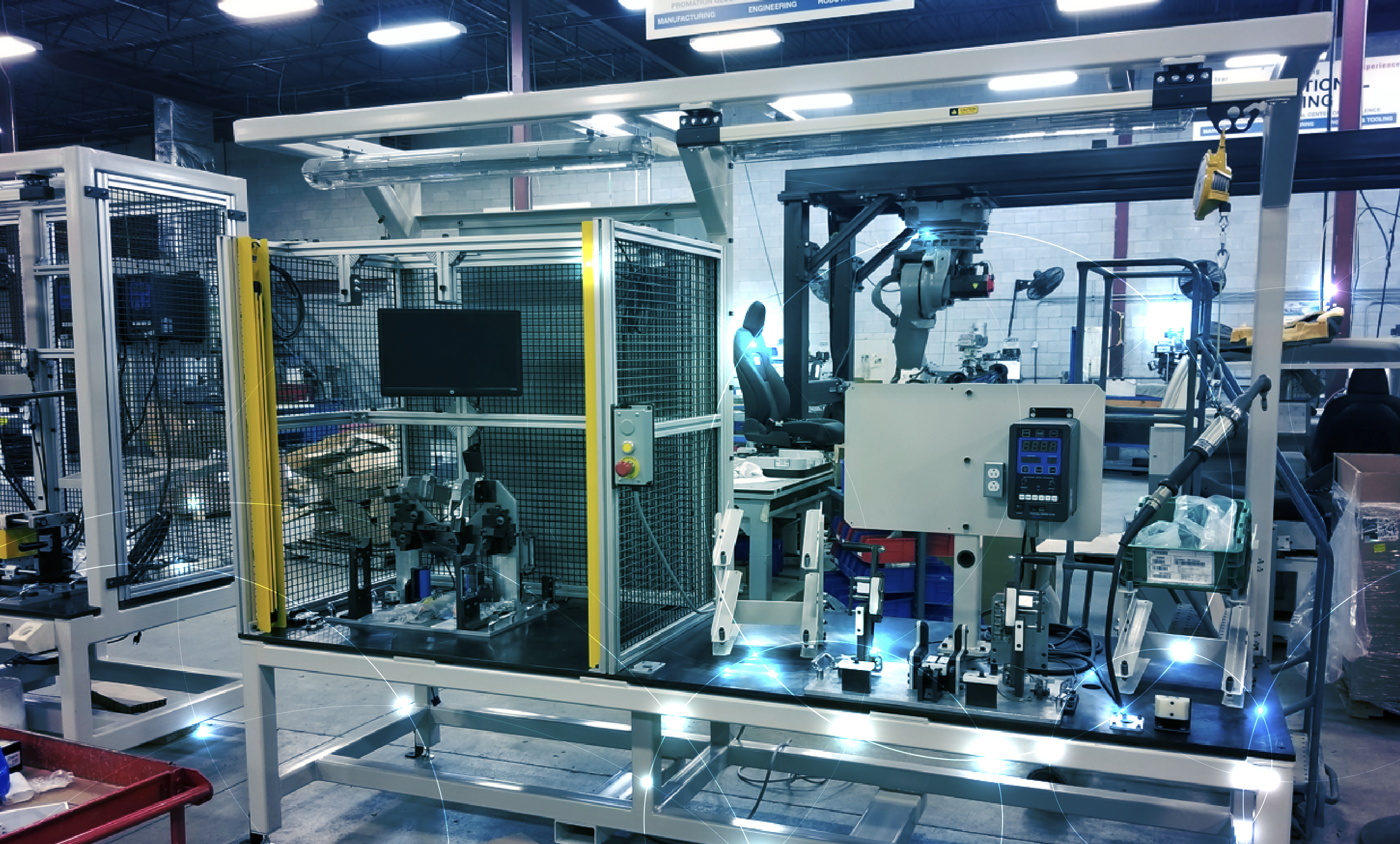

Assembly Build Line Conveyors

You’ve got parts to assemble; we’ve got indexing and continuous moving conveyor solutions to move them. Ensuring that you’ve got conveyor assembly systems designed specifically for your critical workflows is an essential component of any profitable manufacturing operation. Thanks to three decades of advanced manufacturing expertise, Promation offers our customers engineered, proven and tested, fully integrated build line conveyor solutions to optimize your manufacturing processes.

Build Conveyor technologies include:

Pallet-based with tooling for Twin Strand aluminum extrusion conveyors and overhead structure for task lighting and workflow instructions

Slat-based continuous running conveyor with tooling fixtures to build your product off

Overhead conveyors with hanging carrier stations for continuous assembly build process

Assembly work tool stations include auto/manual torque, auto screw guns, quality checks, measurement tools, etc. with automated test stations along the line

Robotic load and offload stations with build lines / inspection station/ bagging station, etc.

Streamline and Optimize

Ask the Promation team how we can assist you in selecting the right build line conveyor systems for your products and add value to your overall manufacturing process to:

- meet or exceed your assembly tack time

- reduce manual strain of assembly line workers

- improve the quality of your finished products or sub-assembly

- lower your manufacturing cost

Automotive Seats Conveyor System

Our client, a global automotive seat manufacturer, required an assembly build line conveyor system with all the testing equipment to meet their growing business demands. Our customer had to triple their seat capacity production within a very limited timeframe.