Complex material handling made simple

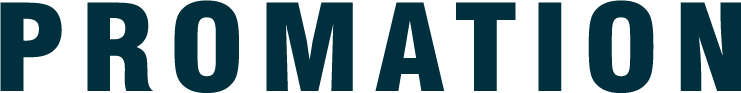

Material Handling Automated Systems

You’ve got parts to move and store … and we’ve got the automated material handling systems to move and place them. Our systems can integrate advanced technologies to ensure that you’ve got the material handling systems that are specifically designed for your critical workflows.

Our Specialty Material Handling Systems can integrate with large OEM assembly lines, or they can be stand-alone turn-key systems for Tier 1 and mid-sized manufacturers, with clean rooms, sanitary, wash down or explosion-proof environments. Our custom systems are developed to meet our customers’ exact market requirements.

Promation may add our AGVs or Industrial Robots to further enhance the productivity of the system; and we have ample automation capabilities to integrate with the numerous material handling specialized devices, such as laser label scanners, laser safety scanners, laser printers and measurement devices like weight systems and many others.

Promation’s Specialty Material Handling Systems are the perfect fit when innovative solutions are required to address difficult and complex manufacturing needs. We supply turn-key systems including tear-down of old systems, design-build of new systems, electrical, mechanical, structural installation, start-up, support and service for the lifetime of the equipment.

Our material handling technologies include:

- Powered and Live Roller, Chain, Right Angle Power Transfer, Rotary Transfer conveyors

- Vertical Lifts for multiple levels

- Automated Buffer Storage multi-level, multi-lane built-in conveyors for automated load and unload

- Automated Retrieval Machines

- Other systems: Lift Assists, Scissor Lift Tables, Medium- and Heavy-Duty Transfer Pallets

- Mezzanines, Catwalks, Ladders, etc. and other structures

Streamline and optimize

Ask how a custom designed Promation Specialty Material Handling System can help you:

Increase your throughput

Reduce space requirements

Reduce manpower

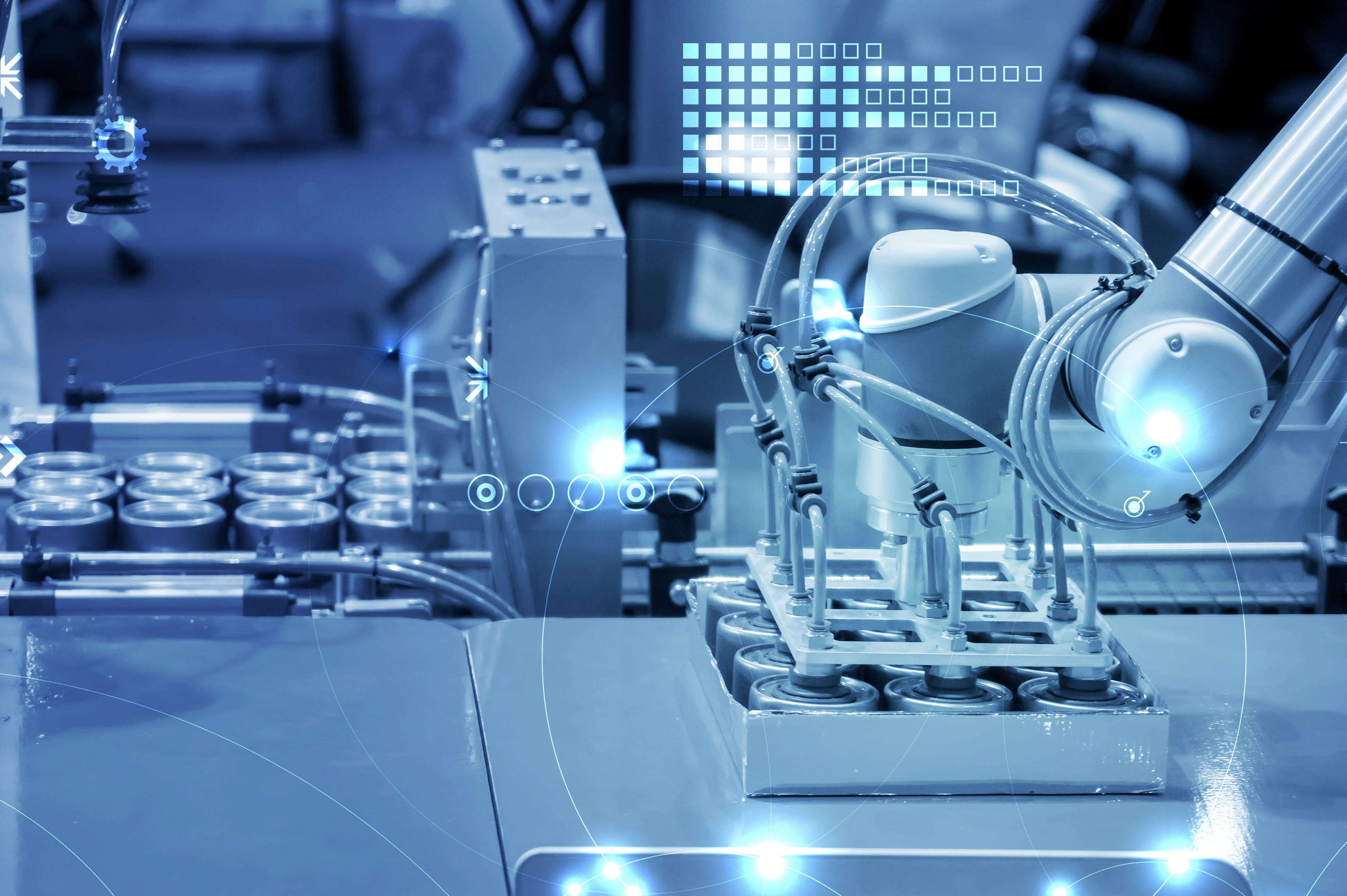

Tire Stack Handling System

Promation designed, built, installed and started up the system within a tight timeframe to full customer satisfaction.

Automated Buffer Bumper Storage

The customer now has an uninterrupted production cycle with no mould change downtime, reduced manpower, reduced part handling damage and significant space savings.

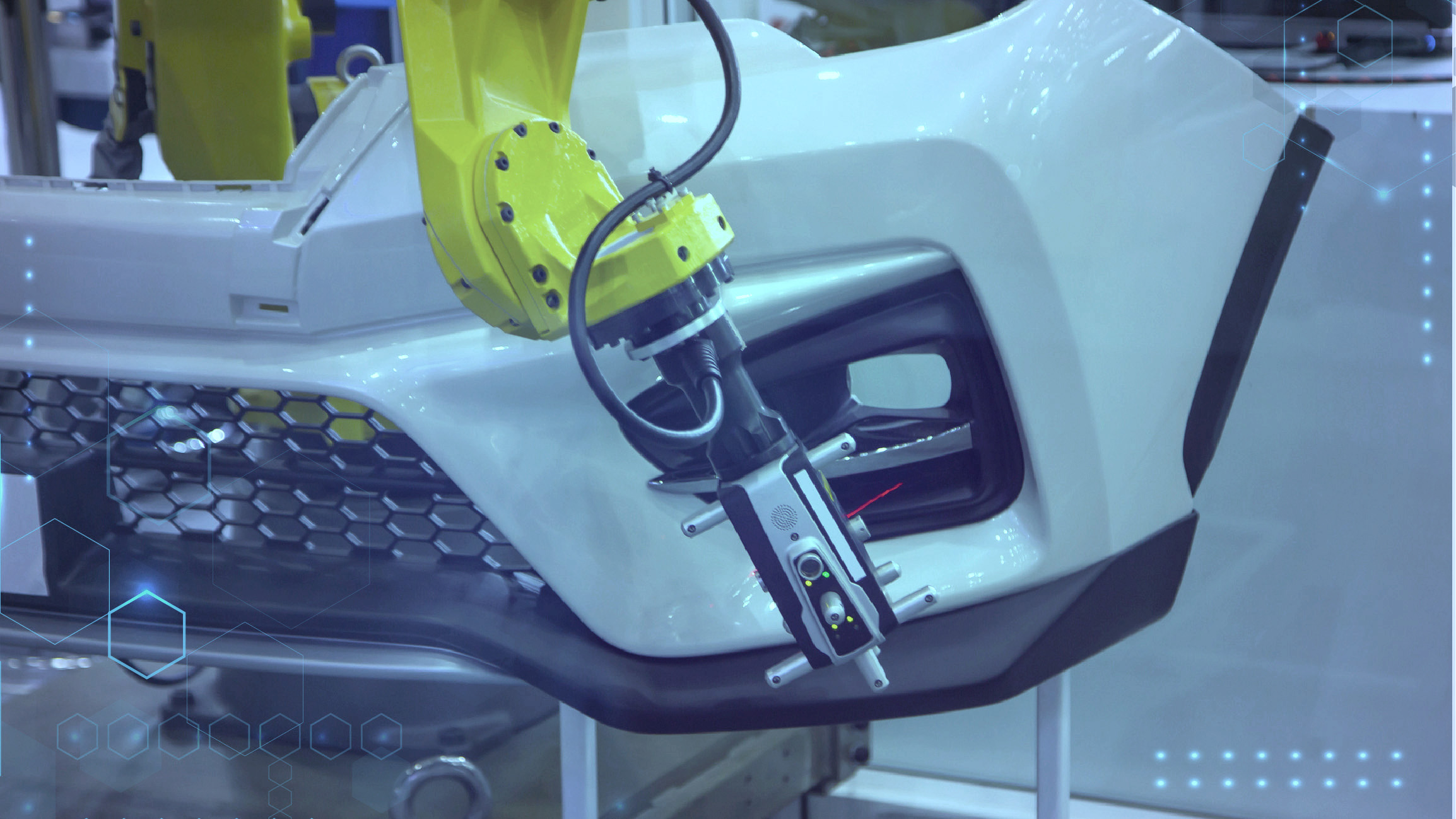

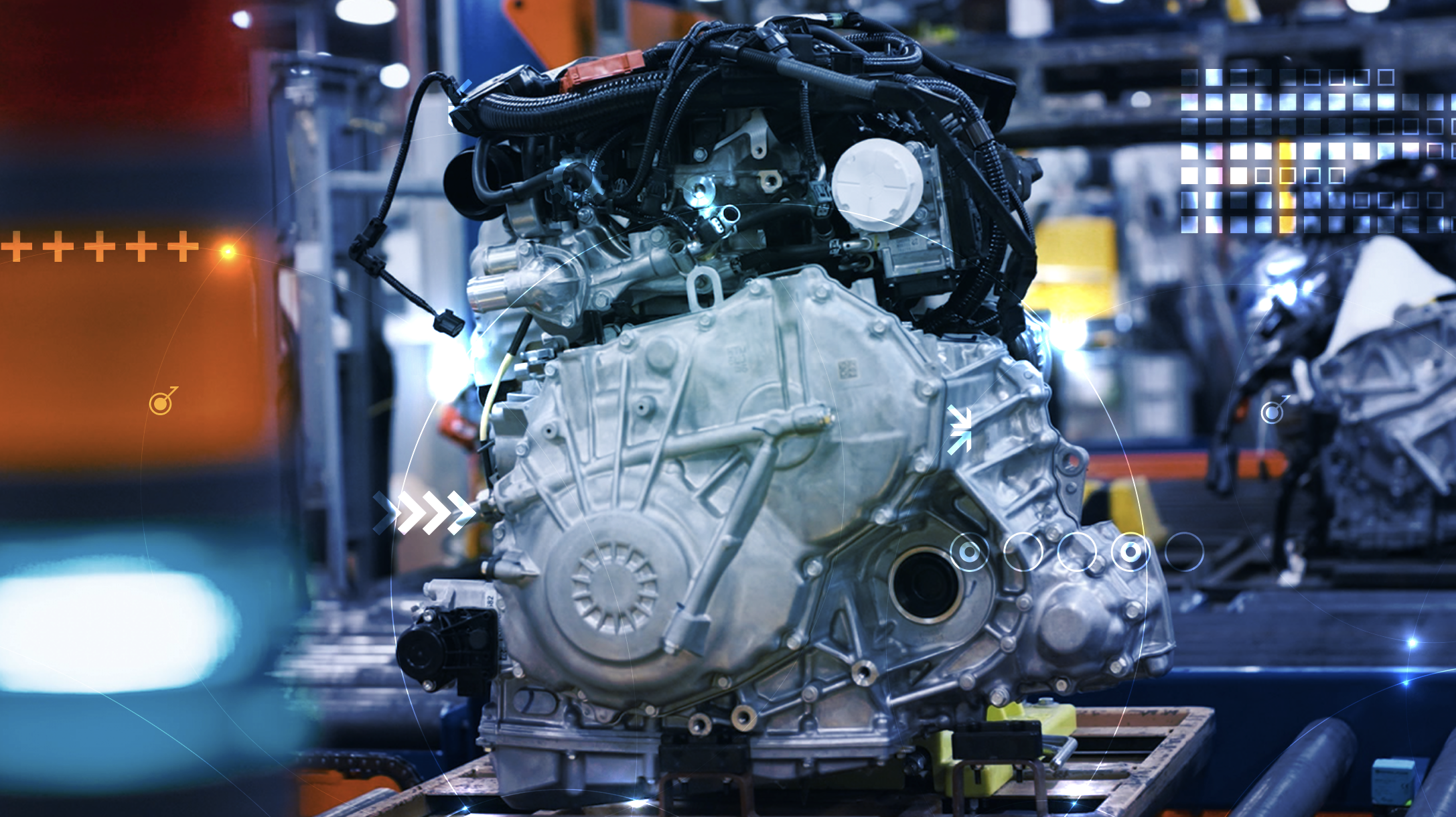

Honda Assembly Line

Promation installed a new engine-moving assembly line in just 10 days.

Featured Works

Front-End Module (FEM) Delivery System

This system is a recycling transfer of FEM sub-assembly from the FEM assembly line to the main car assembly line. The FEM assemblies travel on transfer pallets, with a 59-second cycle time and two-shift operation. The system includes an AGV load station, AGVs travelling autonomously across a busy aisle, AGV unload station, FEM incline accumulation conveyor, FEM Right Angle Power Transfer and FEM Decline Empty Pallet Return Conveyor. The system is fully automated, with superb wireless safety for the AGVs and a complete control system.

Engine Load System

The system features a Loading Engine into a Triple Engine Rack with an automated Engine Pallet. With a 45-second feed cycle time, 20-year lifespan, and two-shift service, it includes a Delivery Conveyor System, Stacker De-Stacker, Pallet Conveyor System with Load and Rotate Station, and Control System.